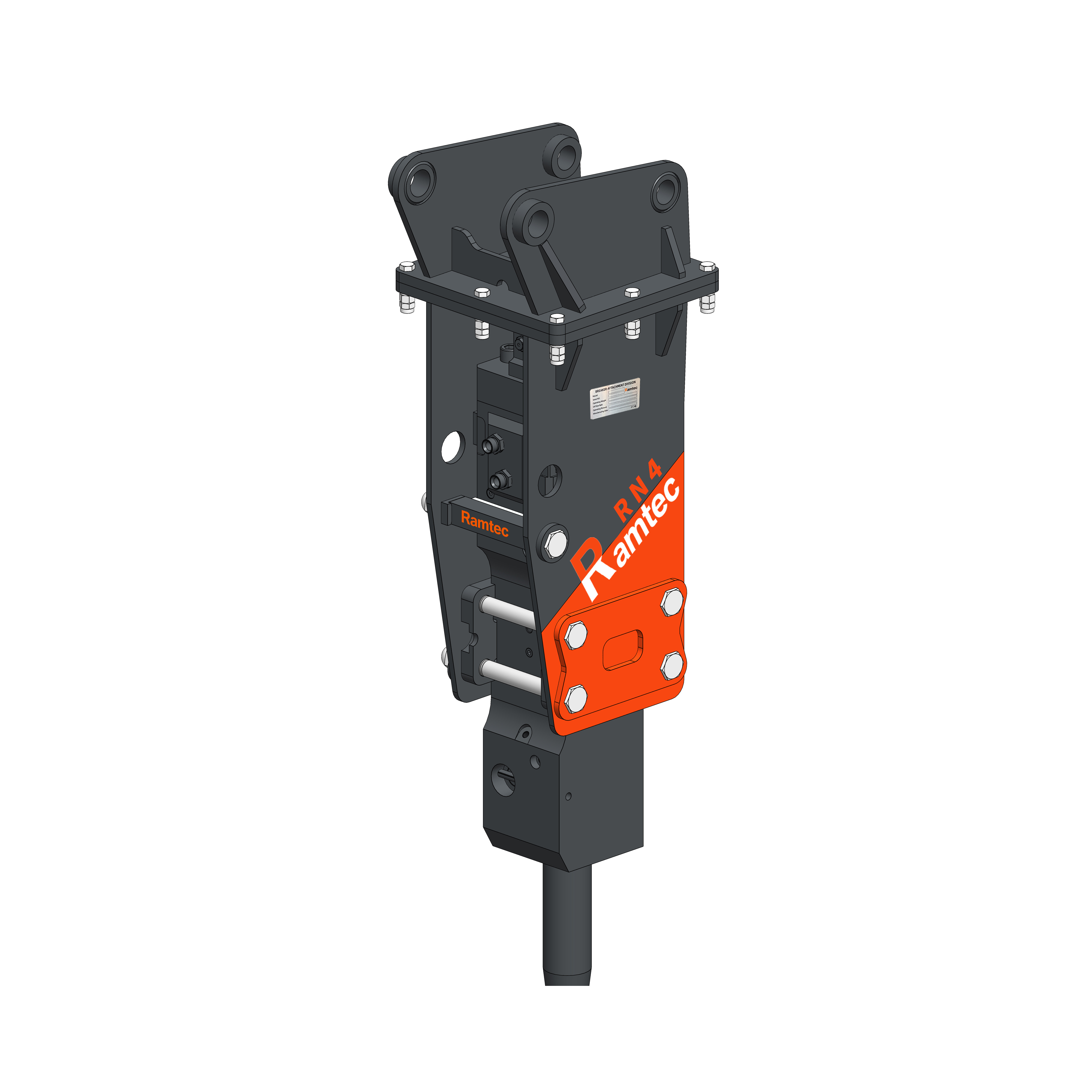

RN Series Hammers

The Five Core Advantages of the RN Series Hydraulic Breakers

1. Higher Impact Energy and Striking Efficiency

Energy Superposition: The striking energy comes not only from the thrust of the hydraulic system but also from the explosive force released instantaneously by the high-pressure nitrogen. The superposition of these two energy sources results in an immensely powerful strike with each blow.

Faster Speed: The expansion speed of nitrogen is extremely high, enabling the piston to achieve far greater acceleration and final velocity compared to pure hydraulic propulsion. This generates higher kinetic energy (E=1/2mv², where velocity v has a squared effect), making it highly effective at breaking rocks, concrete, and other hard materials.

2. Lower Energy Consumption and Enhanced Protection for the Host Machine

"Using Minimal Force to Achieve Maximum Impact": The hydraulic system only needs to compress the nitrogen slowly (sustained low-flow pressure oil), while the instantaneous, high-power striking task is accomplished by the nitrogen. This significantly reduces the instantaneous impact and flow demand on the hydraulic system of the excavator or loader.

Smoother System Operation: The host machine’s hydraulic system experiences a steady load, avoiding equipment wear, overheating, and efficiency loss caused by sudden high-load demands. This means a relatively smaller host machine can be equipped with a larger-class breaker.

3. Faster Blow Frequency

Since the piston’s return stroke (upward movement) is driven by stable hydraulic oil, while the striking stroke (downward movement) is completed by the instantaneous release of nitrogen, the entire cycle is shortened. This enables a higher frequency of continuous blows. The combination of high frequency and high energy results in a qualitative leap in overall operational efficiency.

4. Excellent "Escape" Ability (Anti-Jamming)

This is a critical advantage of nitrogen-powered breakers. When the tool bit becomes stuck after penetrating the material:

The piston continues its downward movement due to inertia, further compressing the nitrogen.

At this point, the compressed nitrogen acts like a cushion, absorbing and storing energy.

The nitrogen then instantly rebounds, pushing the piston back and helping the tool bit free itself from the stuck position.

This feature prevents the breaker from getting "stalled" and unable to work, reducing downtime and protecting the equipment from damage.

5. Superior Protection and Reliability

Cushioning and Vibration Damping: The nitrogen chamber itself acts as an efficient buffer. It absorbs the reactive forces and vibrations generated during the operation of the piston and tool bit, reducing the transmission of these impacts to the excavator’s boom and main structure, thereby protecting the host equipment.

High Reliability: The mature structural design ensures that internal moving components (such as the piston) operate with the cushioning effect of the nitrogen, reducing impact stress and extending the service life of critical components.

Specification

Metric

Imperial

RN3~4

| Description | Unit | RN3 | RN4 |

| Operation weight | kg | 325 | 440 |

| Required oil flow | l/min | 45-100 | 50-135 |

| Operation pressure | bar | 230 | 230 |

| Impact rate | bpm | 500-1150 | 400-1125 |

| Tool diameter | mm | 76 | 86 |

| Impact power | J | 1089 | 1621 |

| Carrier weight | ton | 4-8 | 6-9 |

RN3~4

| Description | Unit | RN3 | RN4 |

| Operation weight | lb | 717 | 970 |

| Required oil flow | gal/min | 12-26 | 13-36 |

| Operation pressure | psi | 3336 | 3336 |

| Impact rate | bpm | 500-1150 | 400-1125 |

| Tool diameter | inch | 3 | 3.39 |

| Impact power | J | 1089 | 1621 |

| Carrier weight | lb | 8818-17637 | 13228-19842 |

Video Show

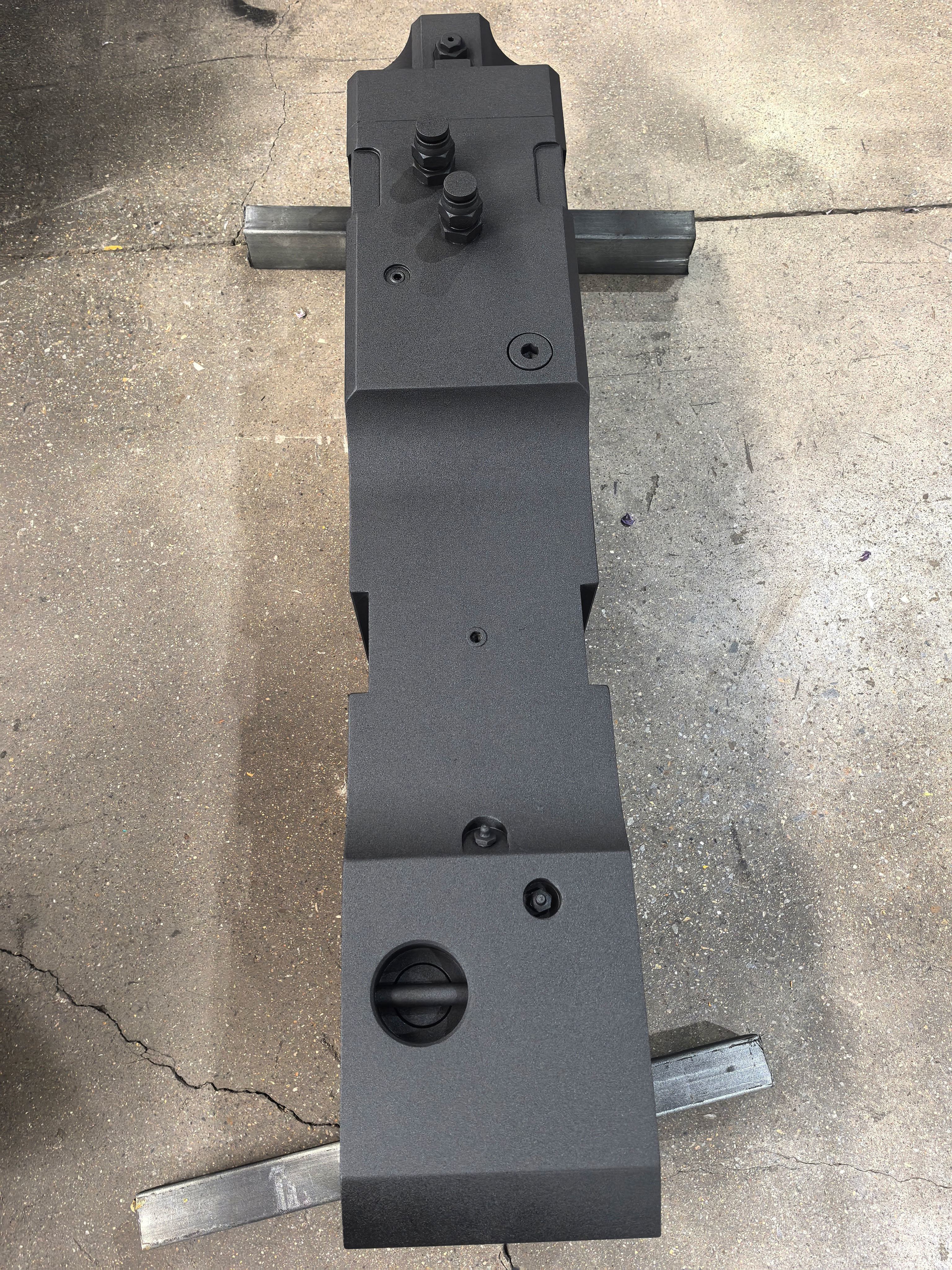

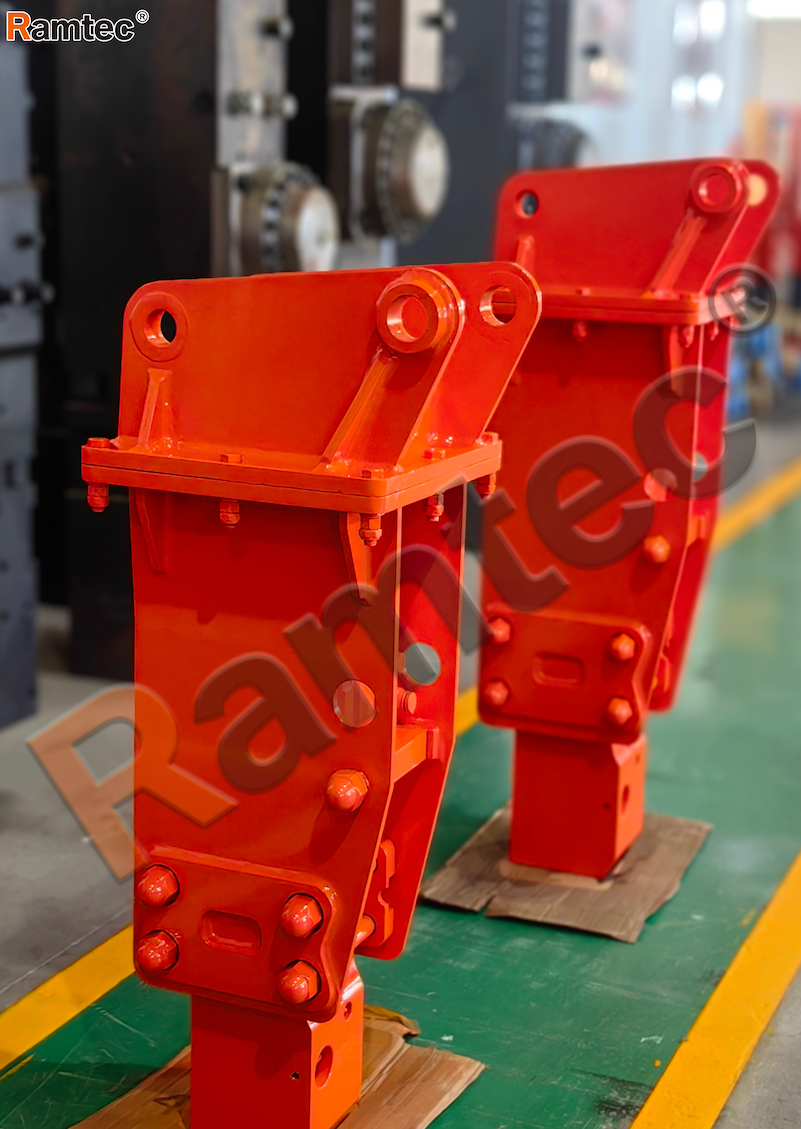

RN Series Manufactured in Ramtec (Hydraulic Breaker/Hammers)

RN Series Manufactured in Ramtec